Capabilities

PRECISION

MACHINING

Our onsite precision machine shop serves as both a production floor and lab. It’s where design, engineering, and machining come together to shape innovative concepts, complete first article inspection, or reverse-engineer parts. The outcomes? Real-world compatible designs, shorter time to production, and simplified purchasing.

DESIGN FOR MANUFACTURING

Our engineering design team focuses their efforts on design for manufacturing. Our shop engineers can develop custom tooling, create prototypes, or work with your manufacturing partners for a smooth hand-off in the engineering process.

PRECISION MACHINING CNC Shop

When it comes to production, we specialize in low-volume, high-precision CNC machining. Some products perform just fine with standard prototype tolerances. We’re here for those that don’t.

Our focus on is on high quality parts, that are small (think rubrics cube verses basketball), complex, and require fast turn times. Our precision machine shop is skilled in handling parts that are difficult to manufacture, parts that others have not made before or that your engineering suppliers struggle with making. Overcoming challenges like difficult geometry (thin walls for example), which can get in the way of manufacturing, is our forte.

Our workhorse for this purpose is the DMU 50 from DMG Mori. It’s our first choice for its five-axis machining capabilities that enable us to create complex shapes in a single setup.

CNC MILLING TOLERANCES

- Metals: +/-0.001″

- Plastics: +/-0.006″

MAXIMUM PART SIZES

- 5-axis: 12 x 12 x 10″

- 3-axis: 30 x 18 x 12″

Tighter tolerances available depending on part geometry.

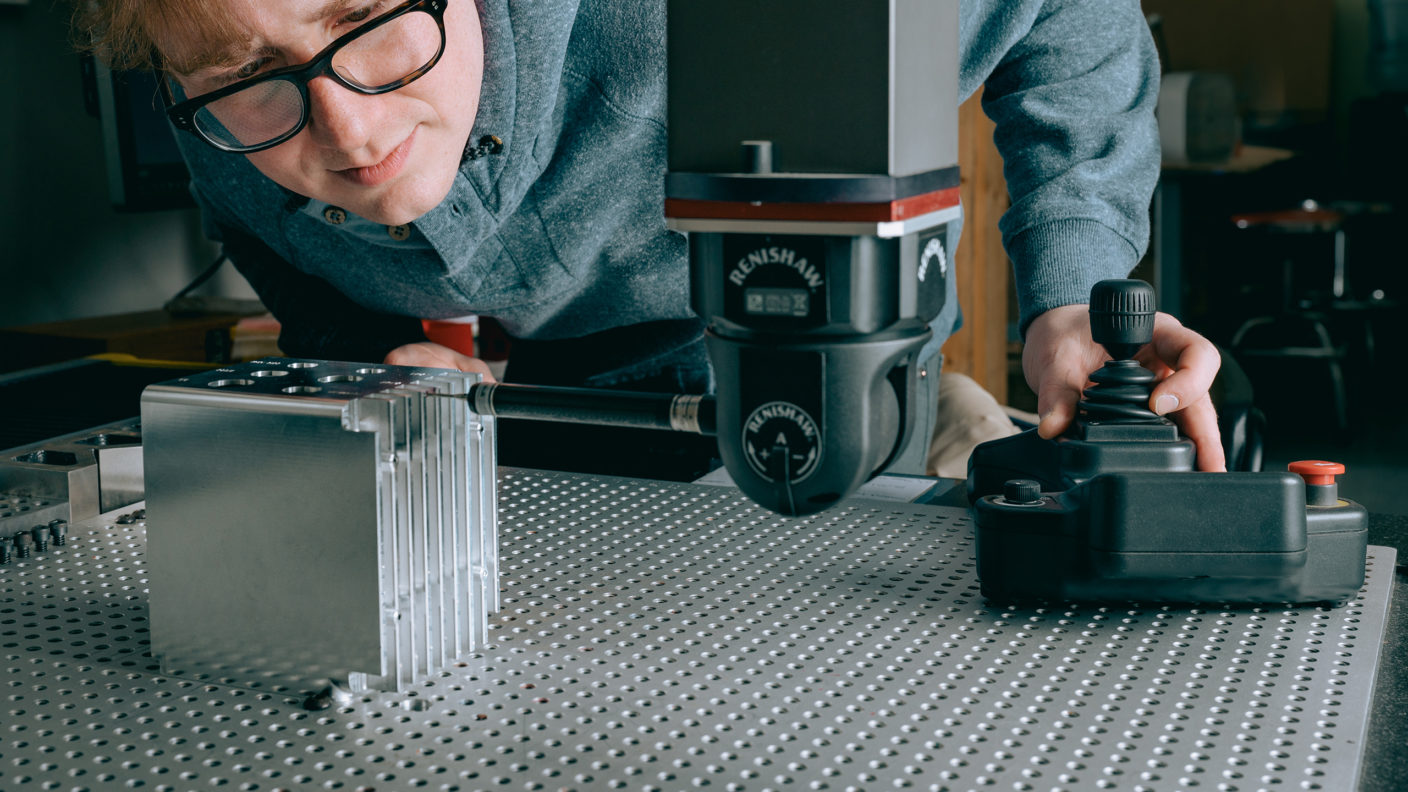

CMM and First Article Inspection

We perform CMM and first article inspection (FAI) for parts we make in-house and as a standalone service that you can outsource. We utilize a Nikon CMM with the Renishaw PH20 five-axis indexing head. From turbine blades and aircraft components to telescope optics, we can handle a wide range of products and deliver:

- Measurement / FAI reports (AS9100 formatted)

- Process validation and change suggestions

- Dimensional part verification

Reverse Engineering

With in-house engineering expertise and precise scanning equipment, we can capture existing products and chart a course to remanufacturing.

ITAR Certification.

Sherpa is ITAR certified. If you require that certification, let us know and we can provide a secure method to share project files for machining.

Customer Stories

We have engineered custom parts for many businesses over the years, here are a few examples. To reduce the manufacturing costs of this low-volume Rohde & Schwarz product, we engineered the case to accommodate different configurations of amplifier systems. Sherpa utilized the fourth axis to reduce setups and save on manufacturing costs for bicycle parts maker Gevenalle.