Capabilities

From concept

to completion

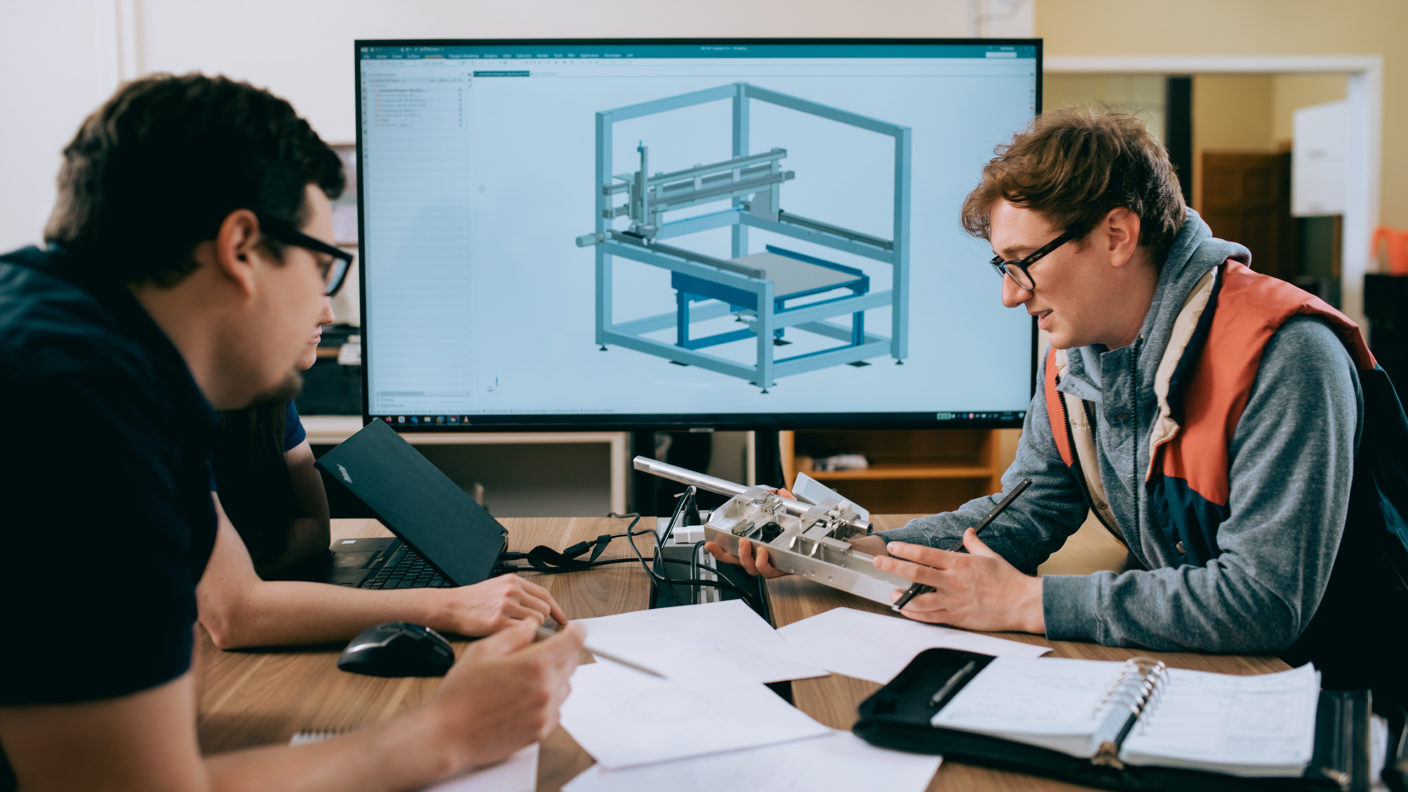

We partner with forward-thinking companies to explore new product possibilities, then guide them from concept sketch to first article and beyond. Whether we take on the full project or a specific portion, you can rely on us for the creative vision, technical depth, and agile M.O. to move it across the finish line.

And we don’t stop there: with in-house manufacturing expertise and robust corporate memory, we can even provide production support and sustaining engineering.

Design & Engineering Expertise

We apply our combined expertise in industrial design, mechanical, and electrical engineering to product development endeavors that entail:

- New design development and design updates

- Prototype production and iteration

- Electronic systems and firmware development

- Productization assessment

- CAD modeling (Siemens, PTC, SolidWorks)

- FEA, thermal and flow studies

- Associative design tool development

- Reverse engineering and 3D scanning

- Physical and environmental testing

- Production and user documentation

How We Make it Possible

From early concepting to full product development and sustaining support, our process is focused, agile, and highly collaborative. See how we easily bolt on to your R&D teams and make your product the best it can be at every stage.

Spotlight: Opto-Mechanical Design

One exciting area in which we’ve applied our expertise is opto-mechanical design. Our experience here spans consumer products (including AR/VR, and automotive), industrial, and defense. Across these domains, we’ve worked with multiple thermal cores, laser modules, optical trains, and ruggedized enclosure development.

We bring deep understanding of: